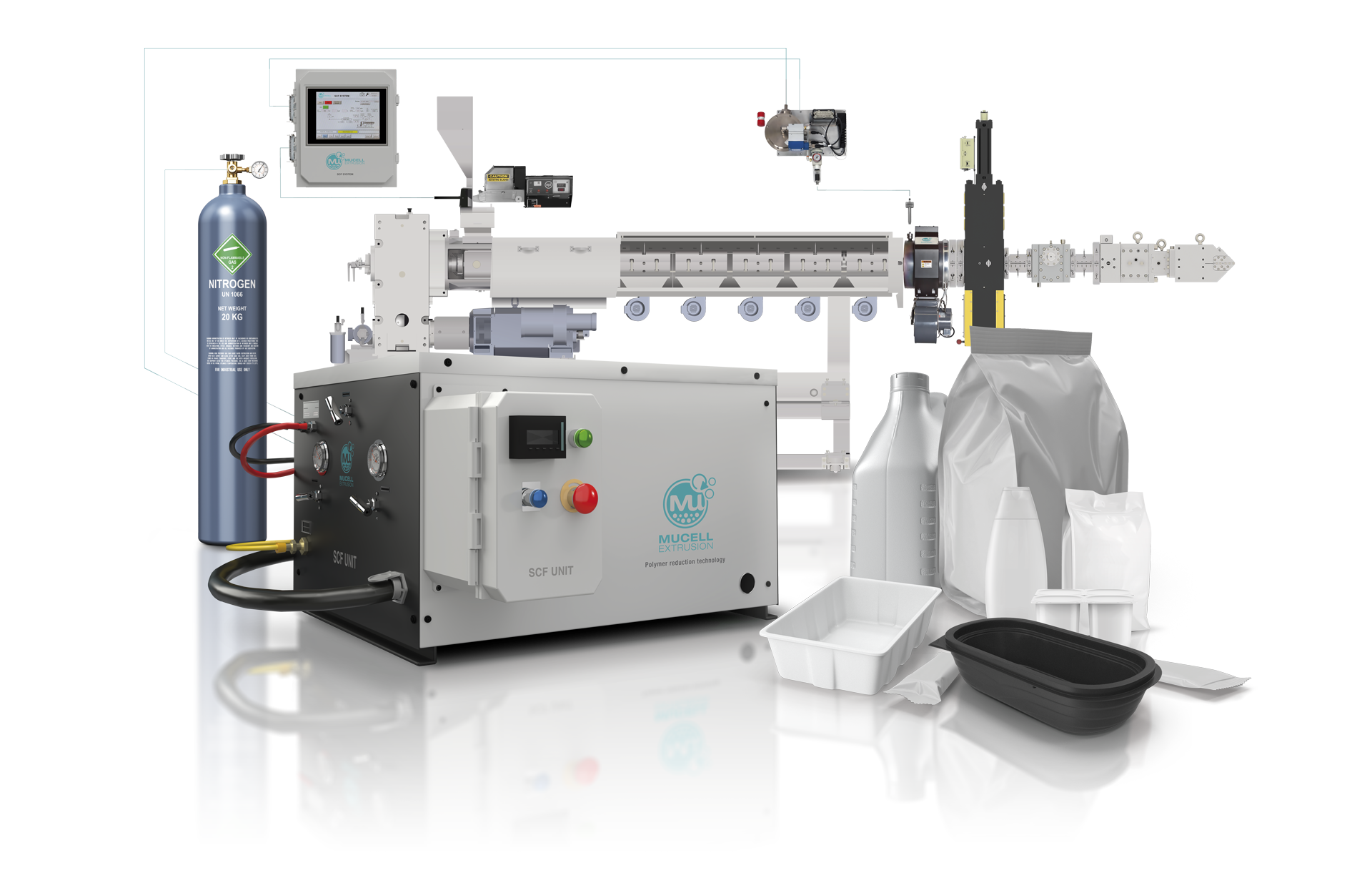

Polymer reduction technology

Create revolutionary microcellular materials that perform like a solid plastic for lighter, greener, lower-cost

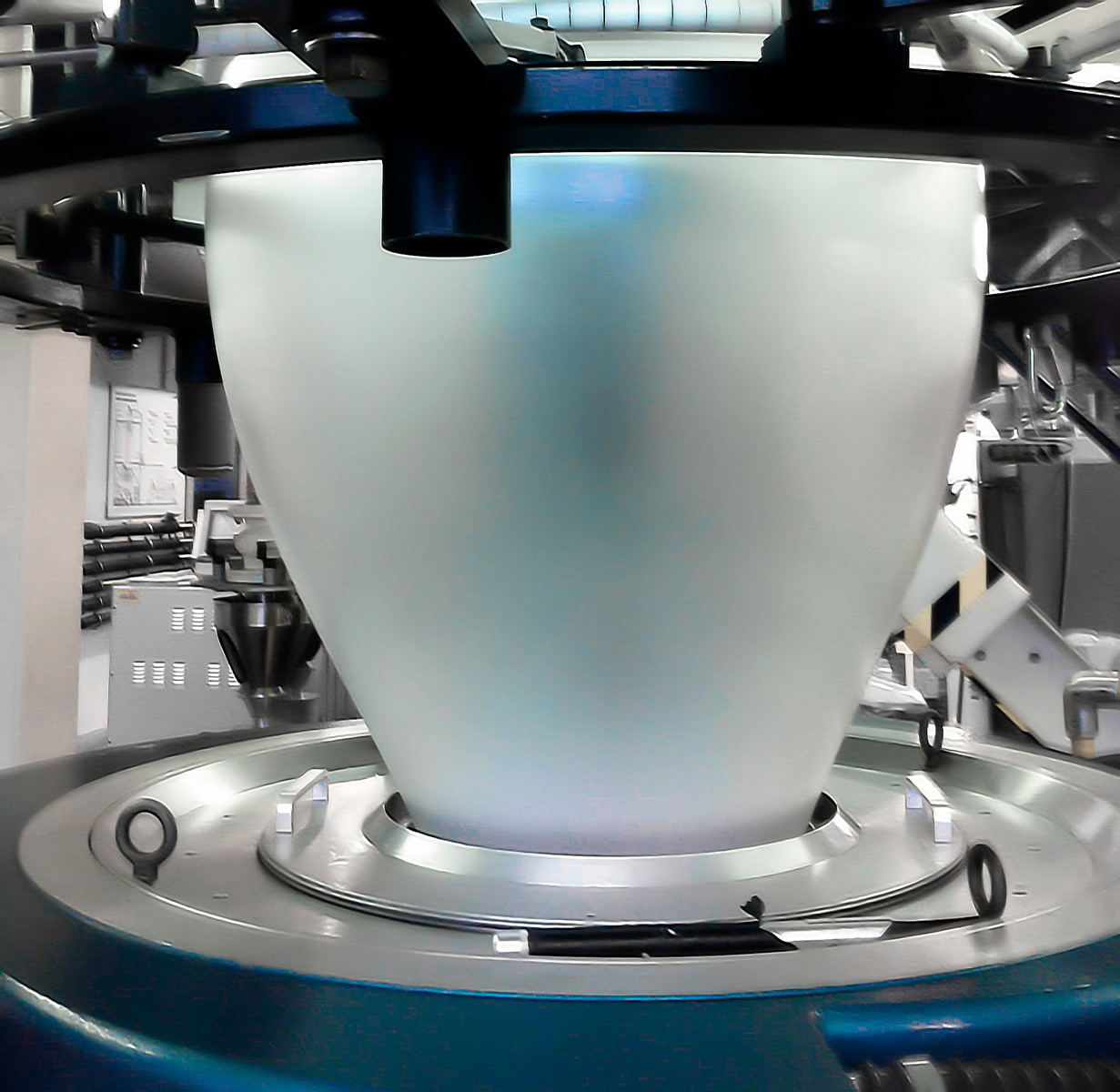

Patented technology from MuCell Extrusion LLC creates a lightweight centre in plastic extrusions by injecting pure atmospheric gas during manufacture. The result is a microcellular, or foamed, core within a solid skin – a single material that looks and performs like a solid plastic yet uses 15-20% less polymer.

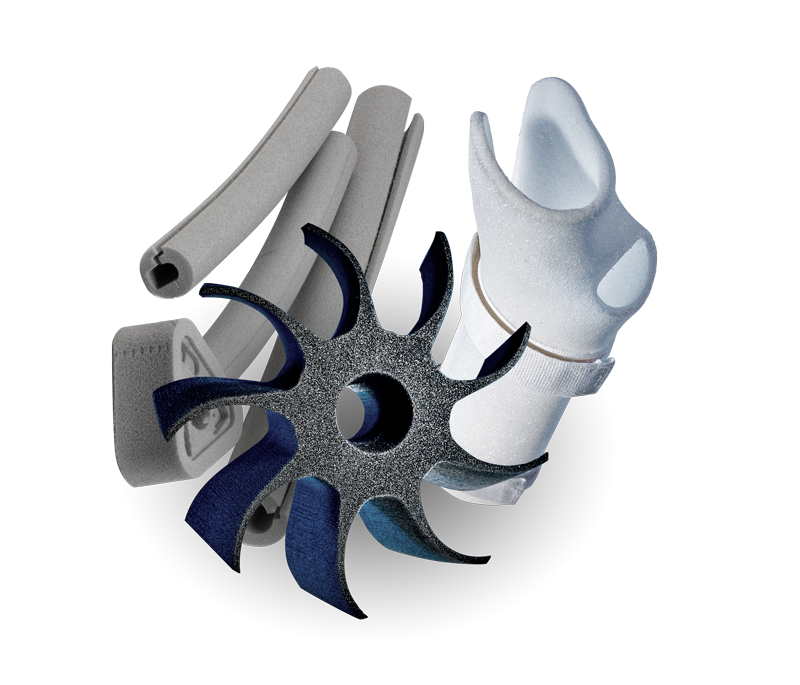

a choice of applications...

MuCell polymer reduction technology can be applied in a wide range of extrusion applications. These materials are then used to make products, such as pouches, sachets, trays, pots and other containers frequently used in volume in consumer packaging, reducing the carbon footprint right through the supply chain. And, after use, the products can be recycled in standard post-consumer waste streams.

The possibilities are endless …

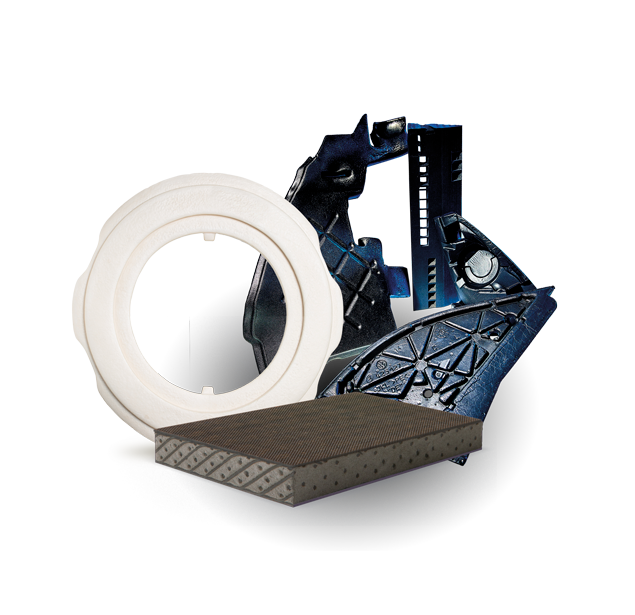

Sheet applications

- Sheet for form-fill-seal (FFS) applications

- In-line thermoforming

- HDFT

- Sheets for signs and displays

- Sheets for construction

- Low-density sheets for gaskets and seals

Film applications

- Lamination films

- Stand up pouches

- Collation shrink film

- Agriculture

- Pet food bags

- Surface protection

Explore more