Lighter, purer, more durable components for the automotive industry

AZOTE® polyolefin foams are manufactured using Zotefoams’ unique, high-pressure process which produces foams that are more consistent, lighter weight and possess higher purity compared with foams manufactured using chemical technology.

Founded in 1949, Odenwald-Chemie GmbH is a Zotefoams development partner and supplier of foam products and fleece systems to a wide range of markets. Headquartered in Neckarsteinach, Germany, Odenwald has a global network of partnerships and joint ventures. It strives to meet ever-changing requirements through innovative products and product optimisation, with environmental considerations always to the fore.

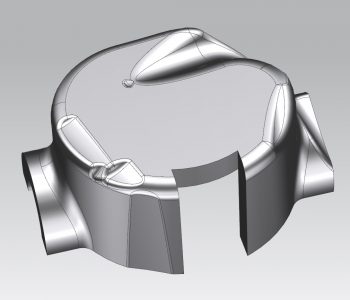

As a longstanding partner of the automotive industry, Odenwald supplies foam products for sealing against water, air and dust, as well as thermal insulation and acoustic absorption. In 2015, Mercedes-Benz requested a valve insulation component able to withstand high temperatures, ensure stable thermal and acoustic insulation and minimise heat loss.

What we did

By selecting Plastazote® HD30 from Zotefoams’ AZOTE® foam range, Odenwald was able to successfully meet the rigorous requirements of Mercedes-Benz. With a density of 30kg/m³ and tolerance of temperatures up to 125°C, HD30 is ideal for addressing sealing and noise, vibration and harshness (NVH) concerns while reducing weight to improve fuel economy. Manufactured via Zotefoams’ three-stage process, Plastazote® has a minimal VOC content compared with foams produced by other methods. Its closed cell, crosslinked structure delivers a unique combination of advantages, including ease of fabrication and purity and high chemical resistance; it neither absorbs nor transmits water or water vapour.

Results

Zotefoams’ unique material combined with Odenwald’s advanced processing technologies produces an energy-efficient product that satisfies the demanding criteria for automotive applications. The valve insulation component was successfully applied to Mercedes-Benz vehicles from 2015 and continues in production today.