New extra-rigid ZOTEK® F OSU foam promises weight savings of up to 70% for aircraft interiors

Zotefoams, a world leader in cellular materials technology, premieres its latest closed cell OSU grade foam, ZOTEK® F OSU XR, promising huge weight savings for aircraft manufacturers, as the company extends its High-Performance Product (HPP) line.

Zotefoams’ latest polyvinylidene fluoride (PVDF) foam, ZOTEK F XR, is an extra-rigid closed cell crosslinked foam available in densities of 120 and 150kg/m3. Complementing the flexible, semi-rigid and rigid grades already available in the ZOTEK F OSU range, the introduction of XR significantly extends Zotefoams’ scope of application in aircraft interiors: ZOTEK F is already used extensively by leading aircraft manufacturers for window seals, soft-touch trim, close-outs, insulation, carpet underlay and environmental control systems due to its light weight, ease of processing and its frequent suitability to replace composite materials. The material also meets all relevant aviation standards, offering outstanding fire, smoke and toxicity (FST) ratings.

“With the introduction of the XR grade, we are extending the weight-saving benefits of the ZOTEK F OSU range to locations such as the interior of seat pods, stowage lockers, rigid armrests and tray tables, reducing weight by as much as 70% on a like-for-like basis,” says James Bridges, Director of High-Performance Products at Zotefoams.

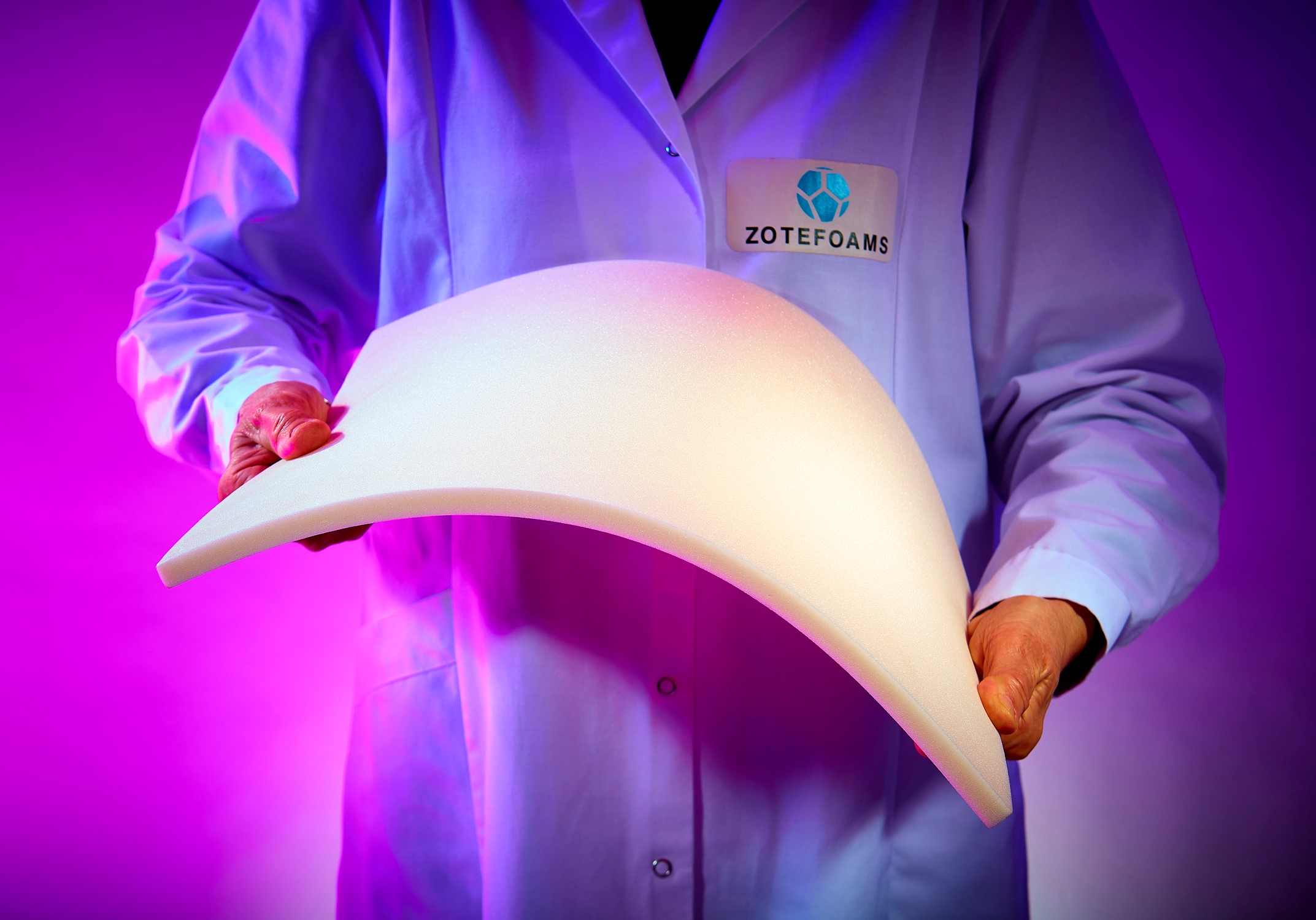

Crucially, grades of ZOTEK F can be laminated together to create a single material that is rigid on one side and soft/flexible on the other and can be formed into curves and complex shapes, opening up opportunities for design teams looking to bring individuality and extra comfort to cabin interiors. With the carbon footprint of air travel firmly in the spotlight, the potential weight savings achievable by replacing solid thermoplastic and silicon components with ZOTEK F are particularly attractive.

ZOTEK is manufactured via a unique process that produces foams with inherently low odour levels and remarkably consistent closed cell structure, characteristics that make the foam exceptionally easy to fabricate via any number of processes including thermoforming, compression moulding, water jet, thermal bonding and lamination.

For more information please contact the ZOTEK team.