Reducing the carbon footprint of pharma manufacturing with high-performance insulation for cleanrooms and utility areas

With businesses the world over focusing on reducing energy consumption for both environmental and cost-saving purposes,

T-FIT® Insulation, a business unit of Zotefoams plc, will showcase its most extensive range yet of high-performance insulation options for pharmaceutical and biotech manufacturers on booth 2158.

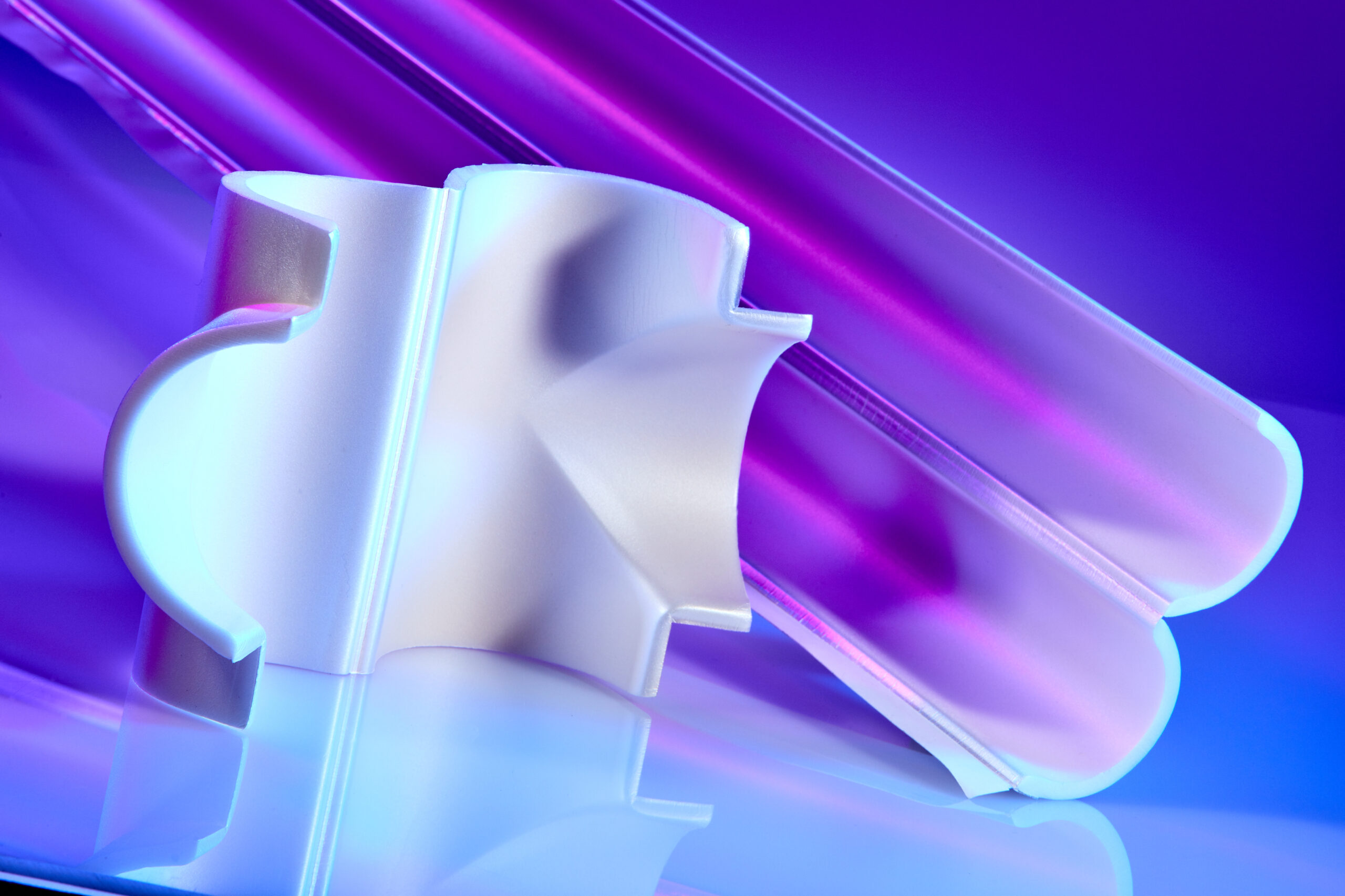

The company’s flagship product for the sector, T-FIT Clean cleanroom insulation, will be shown alongside its latest introduction, T-FIT Hygiene Premium.

Born out of the T-FIT Hygiene range of insulation for aseptic food and beverage production, Hygiene Premium responds to the requirement for some utility areas in pharmaceutical and biotech production to comply with UL 723, the standard for surface burning characteristics of materials. The new range also offers a higher temperature tolerance than standard T-FIT Hygiene.

Anticipating significant growth in demand, Zotefoams has also established manufacturing capabilities for T-FIT products in the USA, allowing local fulfilment of orders.

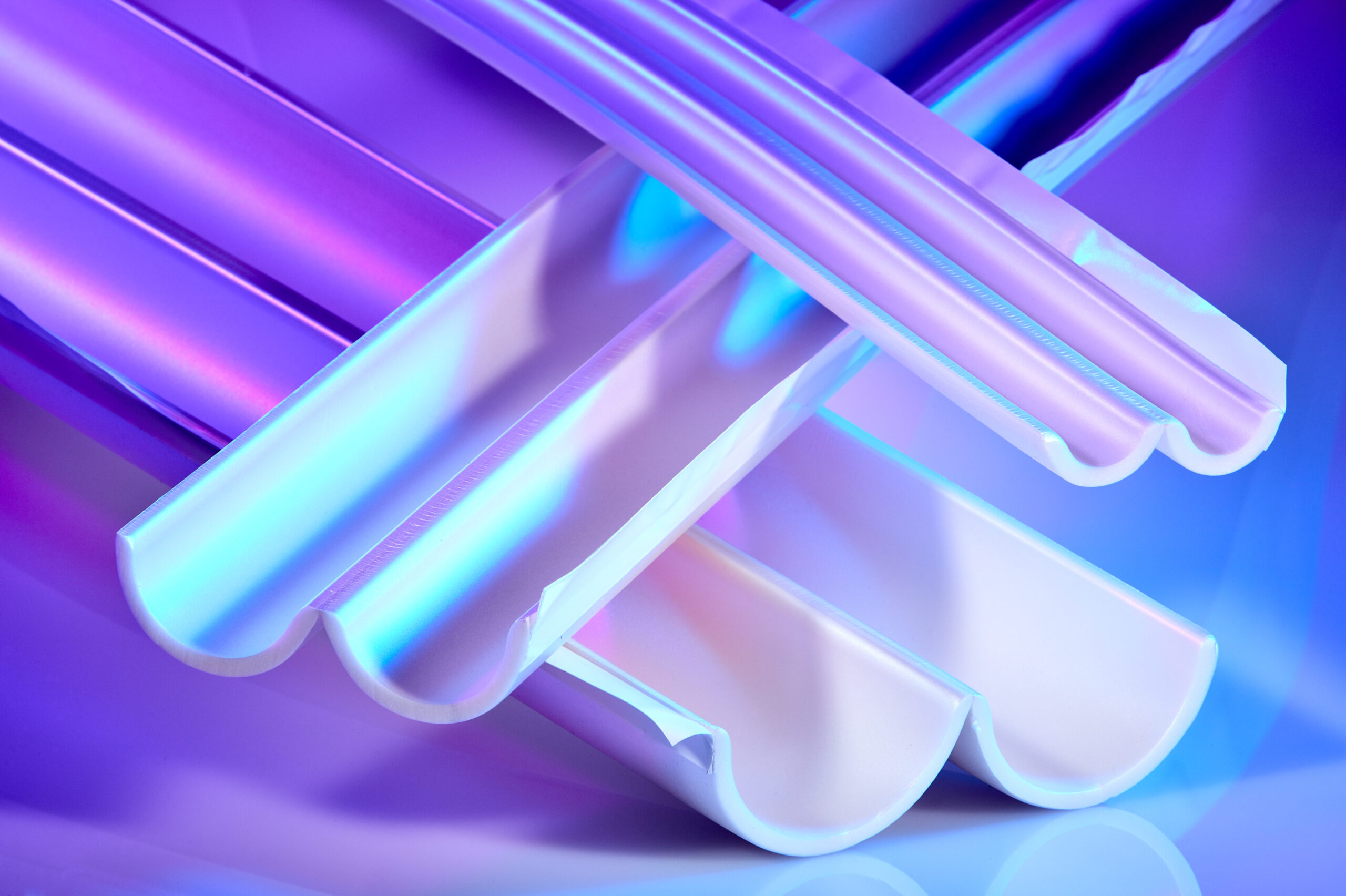

Designed initially as a modular foam insulation system for pipework in cleanrooms, The T-FIT range has subsequently been extended to include ranges for the food and beverage manufacturing sector, and for high-temperature processing environments.

All T-FIT products are manufactured from closed cell, crosslinked foams in Zotefoams’ ZOTEK® high-performance product portfolio and produced via a proprietary method that delivers pure, durable, consistent and lightweight materials that do not shed particulates, have a wide temperature tolerance range and are inert, meaning that they do not promote mould or bacteria growth.

Additionally, the foams have excellent resistance to chemicals and T-FIT Clean, T-FIT Hygiene Premium and T-FIT Hygiene, manufactured from PVDF, have inherent UV resistance.

Uniquely, T-FIT Clean also meets and exceeds all relevant global standards for cleanroom insulation, including the FM4910 fire-retardant property standard.

Modular pipework insulation in the T-FIT range boasts a slim profile and quick installation. The company is also offering the materials in sheet form for insulation of walls, bulk tanks and other equipment, and as pre-formed ducting for HVAC applications, extending the T-FIT suite of benefits to most production requirements.

T-FIT® Clean is the only closed cell foam insulation system that is suitable for both pipes and walls within a cleanroom environment. Uniquely, it also meets and exceeds all relevant global standards for cleanroom insulation, including the FM4910 fire-retardant property standard.

Zotefoams Director of HPP Products, James Bridges, says, “With the focus on environmental considerations extending to all corners of industry, we are excited to bring our most complete portfolio yet of T-FIT insulation to Interphex. Fundamentally more sustainable than traditional forms of insulation thanks to its superior longevity, T-FIT is also a sound economic choice, offering the highest levels of performance and compliance with relevant standards combined with quick and easy installation, plus low maintenance requirements.”